Precision Laser Cutting & Metal Fabrication for Commercial and Industrial Manufacturers, located in Columbus Wisconsin

Established 2013 - locally owned and operated

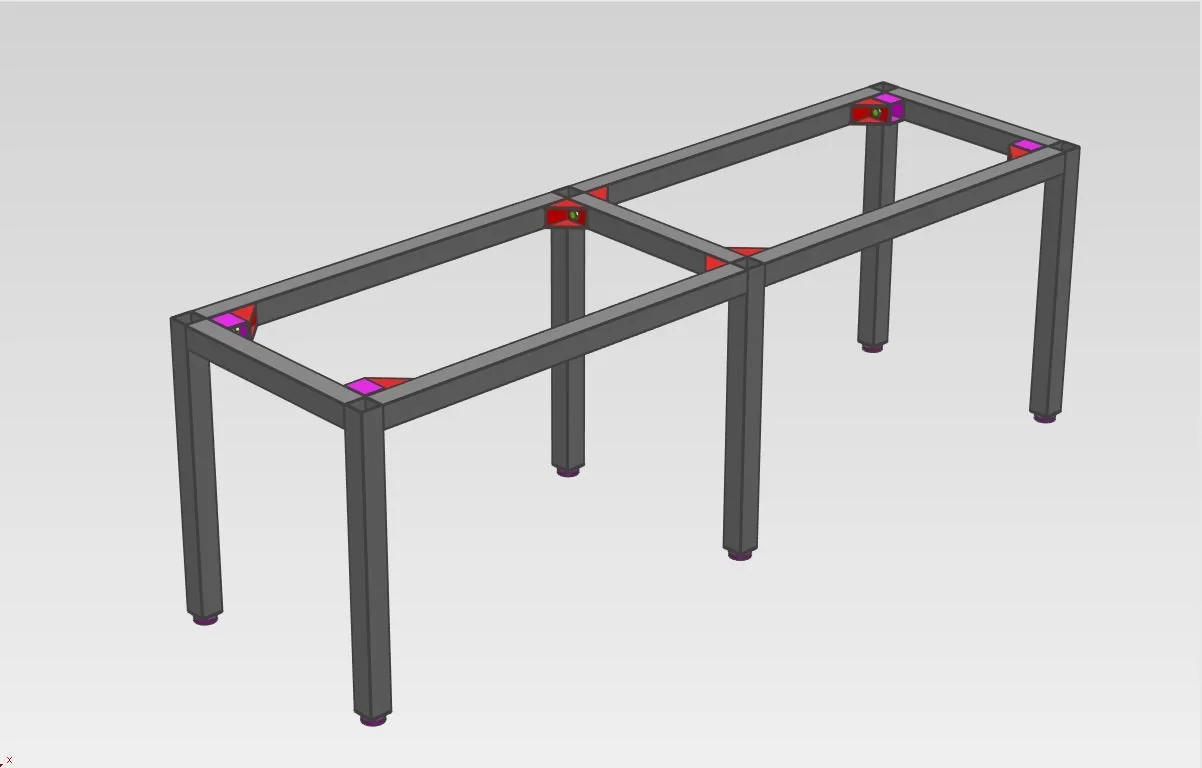

Process Revolution LLC is a Columbus Wisconsin-based company delivering precision fiber laser cutting for commercial and industrial manufacturers for low to mid-volume production. Our production workflow is built on documented, ISO‑inspired process controls for consistent, repeatable results.

We specialize in repeatable, weld-ready parts with tight tolerances and clean edges — delivered on time and on budget.

Need verification? We offer probe-based inspection and logged documentation, available on request for clients who require traceability.

While fiber laser cutting for manufacturers is our core production service, we also offer a range of supporting capabilities — including CAD design, CNC machining, forming, shearing, punching, welding, assembly, and paint. These services support everything from prototyping, launch‑phase and low volume builds. Based in Columbus, Wisconsin, we serve customers throughout the surrounding areas with fast quoting, consistent quality, and traceable documentation.

Whether you're scaling a product line or refining a one‑off design, we bring precision, flexibility, and professionalism to every project we take on.

1. Request A Quote form

Fill out the form & upload your DXF. We will respond with what else is needed.

2. We Review & Quote

We validate your files, flag any issues, and send a clear, professional quote.

3. We Cut & Inspect

Parts are cut on our fiber laser with tight tolerances and clean edges. If inspection is selected, we log DRO measurements and generate a pass/fail report.

4. You Get Parts

Parts ship out clean, labeled, and ready for your next step, or you can pick them up at our Columbus shop.

How It Works

Production Services

Cut. Inspect. Ship. - Fast, Local, Reliable

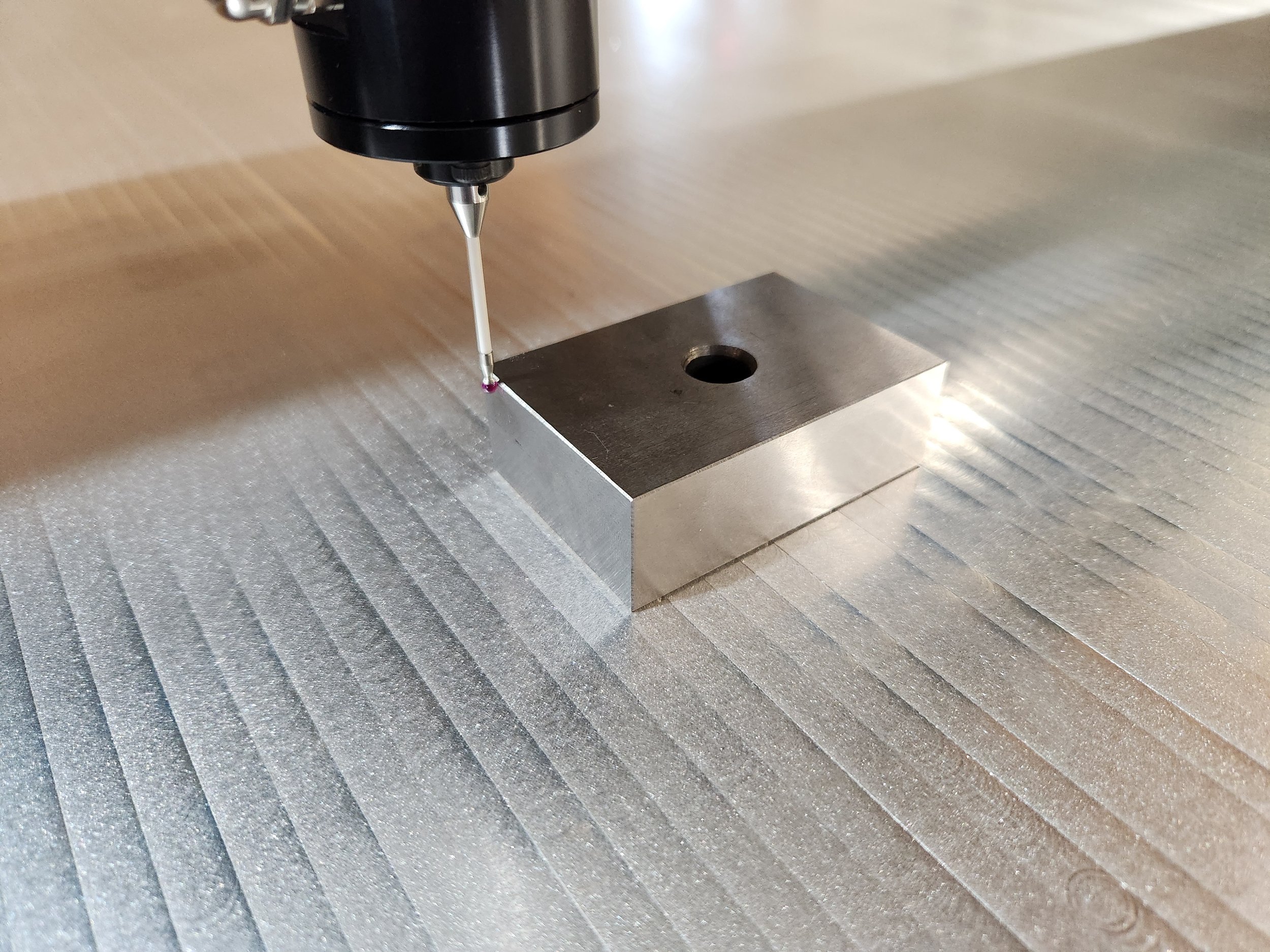

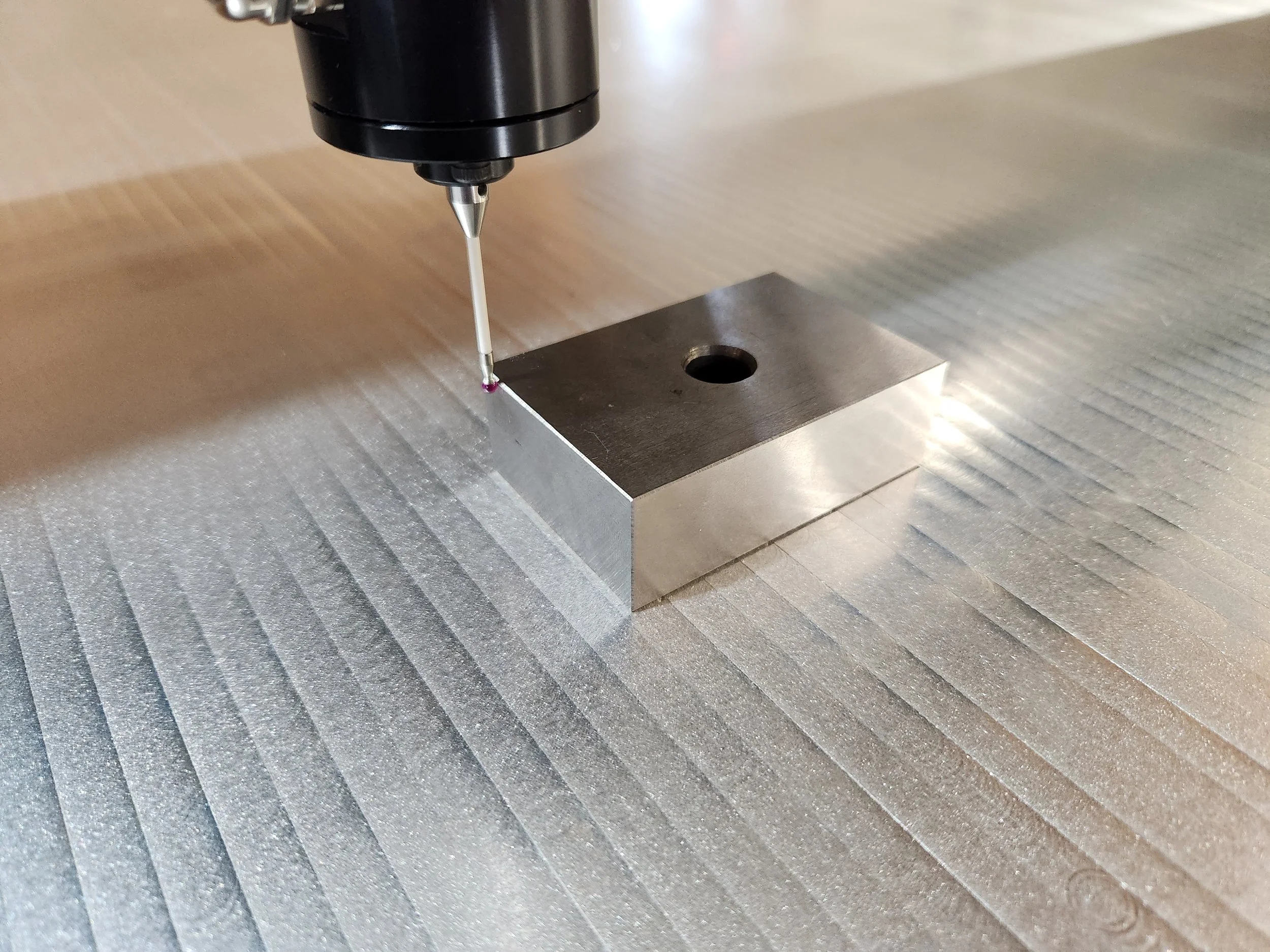

How We Inspect

Custom Probe Routines, Traceable Results

We run custom probe routines on a dedicated CNC platform. Raw machine data is used to reconstruct geometry, verify critical features, and generate inspection reports with clear pass/fail verdicts — all based on traceable, timestamped measurements.

This process was developed in‑house to meet our standards for transparency, repeatability, and inspector‑grade accountability.

Supporting Capabilities